Case study no. 16:

Plating om Plastics (PoP)

Initial situation

Although surface coatings in electroplating are usually associated with the treatment of metallic parts, metallic coating processes can also be used with great success on non-electrically conductive surfaces. The application of a metallic coating can greatly improve the functionality, look and feel of plastic surfaces in particular. The metallic coating of plastics originally comes from vehicle construction, which in the 1960s and 70s required a reduction in fuel consumption through lightweight construction. Today, metal-coated plastics can be found, for example, in bathroom fittings, control elements, buttons in the clothing industry and a variety of household products and everyday items. A variety of different plastics can be metal-coated, but 90% of coated plastic surfaces are made of ABS.

Task definition

Applying a durable and attractive metallic coating to a plastic component is a very complex process and requires a high degree of process engineering precision. Prior to the actual electroplating process, the surface must be extensively pre-treated, e.g. by cleaning, pre-dipping, pickling, pre-treatment, neutralization, pre-activation, activation and acceleration, until it can then be chemically nickel-plated. This is followed by a series of electrochemical treatments to improve the aesthetics and mechanical properties. Alkaline and strongly acidic chemical baths containing corrosive media ranging from sodium hydroxide (NaOH) to sulphuric acid (H2SO4) and hydrofluoric acid (HF) are used in these processes. To ensure that the processes in the individual baths run efficiently, they have to be kept at a precise temperature range of 20°C to 80°C. Not only heaters are used here, but also coolers to dissipate the electrical power loss. The Immersion-Type heat exchangers used for this purpose must be resistant to the products used over the long term and offer maximum performance with a small footprint in the process tank.

Solution

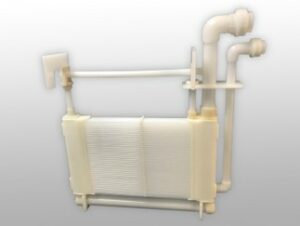

The Calorplast Immersion-Type heat exchangers made of PP (polypropylene), PE-RT (polyethylene for raised temperatures), PVDF (polyvinylidene fluoride) and stainless steel (1.4571, 1.4301) are unique on the market due to their design and high surface density.

Due to the very specific requirements of each individual process step, each heat exchanger is designed and constructed for the respective process tank.

Result

Calorplast heat exchangers have been impressing customers for over 35 years. The quality and supply of all heat exchangers from a single source ensures the correct temperature control of the entire process.