Sulphuric acid dilution

Case study no. 20: Sulphuric acid dilution Initial situation Large quantities of sulphuric acid…

If you are looking for an efficient, durable and economical solution for your heat exchanger needs, plastic heat exchangers from CALORPLAST are the ideal choice. But why exactly should you choose our products?

Our bath heat exchangers are the de facto standard for use in highly concentrated acids and aggressive liquids. For decades, leading companies have relied on our unique, patented technology, which guarantees absolute corrosion resistance and an outstanding service life. Thanks to high-quality engineering plastics, our heat exchangers are not only extremely robust, but also easy to clean and maintain.

The compact design enables seamless integration into existing systems and ensures maximum performance in the smallest of spaces. Our modular systems can be flexibly adapted and offer the perfect solution for every application.

With CALORPLAST bath heat exchangers, you reduce downtime, lower operating costs and increase the efficiency of your processes. If you do without this technology, you are giving away money – no other solution offers a comparable combination of efficiency, longevity and cost savings.

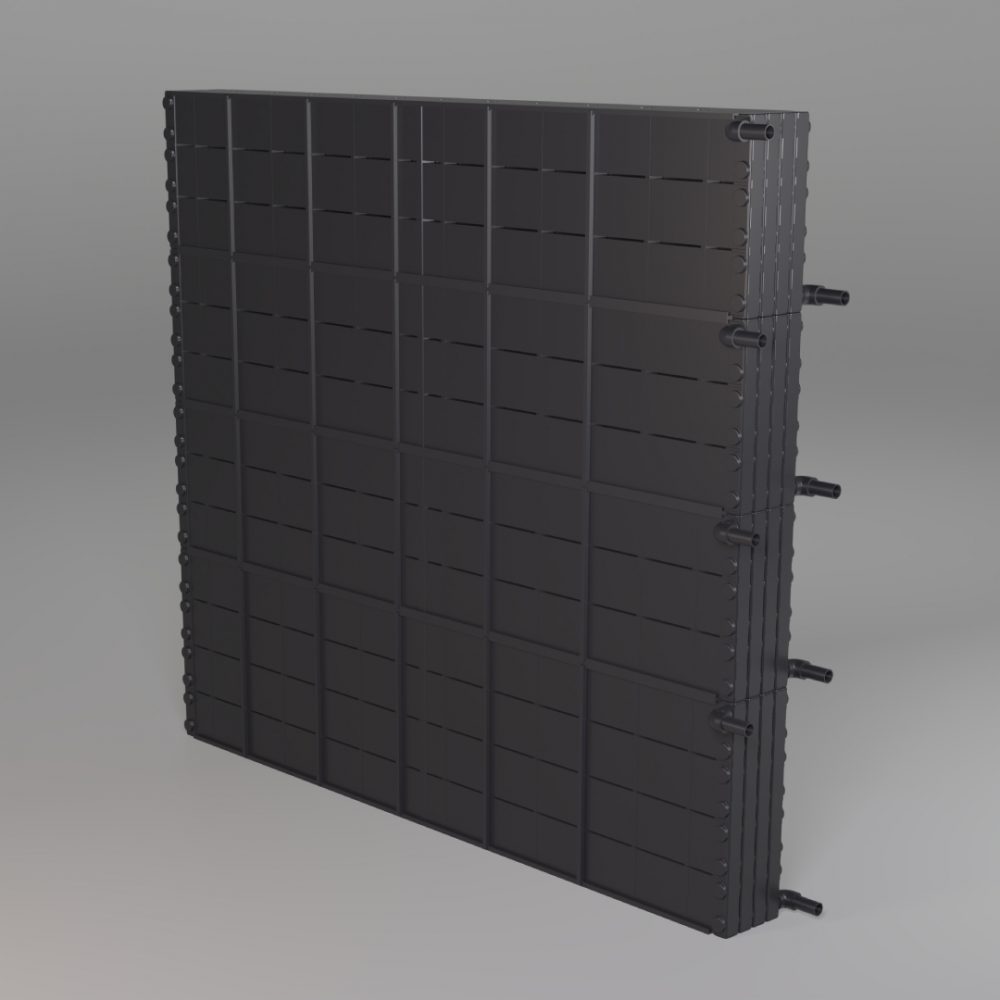

The tube plate heat exchangers from CALORPLAST set standards in the chemical industry. They are characterized by their compact design and high transfer rates and are made entirely of corrosion-resistant plastic. This means: maximum efficiency and a long service life, even under the toughest conditions.

Our heat exchangers enable extremely efficient heat transfer with minimal space requirements on the skid. Thanks to their modular design, they are available in various sizes and configurations so that they can be perfectly adapted to the specific requirements of your system – whether in small laboratories or in large industrial plants.

With the tube plate heat exchangers from CALORPLAST, you are investing in a solution that not only saves space and resources, but also reduces your operating costs. Don’t miss the opportunity to optimize your processes with the best technology on the market.

Our CALORPLAST shell and tube heat exchangers are the ideal solution for the efficient heating, cooling and condensation of pure and ultra-pure media. These external heat exchangers of classic design combine a compact design with high heat transfer performance, thanks to the use of thin-walled tube bundles made entirely of corrosion-resistant plastics.

Especially in laboratories, testing facilities and test setups that work with aggressive and corrosive media, our tube bundle heat exchangers have proven to be indispensable. Their small size allows for easy integration, even in confined environments, while their robustness and efficiency minimize operating costs.

With CALORPLAST, you can rely on a solution that is not only compact and cost-effective, but also impresses with its durability. If you choose not to use our shell and tube heat exchangers, you are missing out on the opportunity to save space, reduce costs and achieve first-class performance at the same time.

CALORPLAST gas-water heat exchangers are the key to future-proofing your system. They enable highly efficient heat recovery from contaminated air and the safe treatment of corrosive gases – perfect for industrial applications where aggressive gases and vapors occur. Thanks to their robust construction made of corrosion-resistant plastics, they are particularly durable and resistant to aggressive process media.

With our heat exchangers, you can significantly increase the efficiency of your heating and cooling systems, while at the same time considerably reducing your operating costs. The investment in CALORPLAST pays off quickly: Due to the high energy savings, the heat exchangers pay for themselves in a very short time and contribute to a sustainable reduction in costs in the long term.

Anyone who relies on CALORPLAST gas-water heat exchangers is investing in a durable and economical solution that not only meets current requirements, but also future ones.

Our Evolution Series is the next generation of CALORPLAST gas-to-water heat exchangers and sets new standards in efficiency and compactness. With further increased performance, reduced space requirements and low weight, these heat exchangers are the ideal solution for demanding applications. The Evolution Series embodies the pursuit of innovation and the outstanding quality that characterizes CALORPLAST.

Developed in close cooperation with our customers and taking into account the latest technological advances, this series combines high performance and flexibility in a compact design. The use of high-performance plastics and advanced manufacturing techniques enables unprecedented efficiency and adaptability. The Evolution Series is not just a further development – it is the future-oriented solution for all those who place the highest demands on their heat exchangers.

The biogas heat exchangers from CALORPLAST represent a globally unique technology that has been specially developed for drying biogas. Thanks to their complete construction from high-performance plastic, they are absolutely corrosion-resistant, extremely durable and easy to install and maintain. These features make our heat exchangers the first choice for biogas plant operators who are looking for efficiency and reliability.

Our heat exchangers easily withstand the extreme conditions in biogas plants and ensure constant performance over many years. By reducing moisture and improving biogas quality, they make a significant contribution to optimizing the entire biogas production process.

When you choose CALORPLAST biogas heat exchangers, you are investing in a technology that is not only easy to maintain, but also guarantees a long service life and reliable performance – a combination that is unique in the world.

Our plastic heat exchangers are characterized by their outstanding properties:

Use in a wide range of temperatures. Depending on the application and design, the heat exchangers can be used in a wide temperature range, from sub-zero temperatures to the three-digit Celsius range.

Efficient heat transfer despite the use of plastic materials. Our heat exchangers are designed to offer a maximum heat transfer rate, resulting in improved energy efficiency.

Durable and resistant to aggressive chemicals. Thanks to the use of special plastics, our heat exchangers offer excellent resistance to corrosive and aggressive media, which significantly extends the service life of the devices.

Suitable for high pressure loads. The robust design of our heat exchangers ensures safe operation even under normal operating pressure conditions.

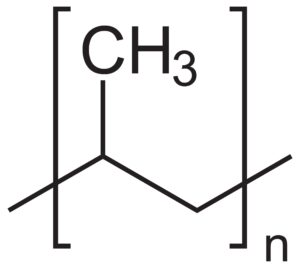

PE offers excellent resistance to most acids and bases. Thanks to its flexibility, versatility and durability, PE is an excellent choice for a wide range of industrial applications. CALORPLAST uses the variants PE-RT(raised temperature), which is permanently suitable for higher temperatures (up to approx. 80 °C) in corrosive environments, and PE-HD(high density), which has a comparatively high strength combined with a low overall weight.

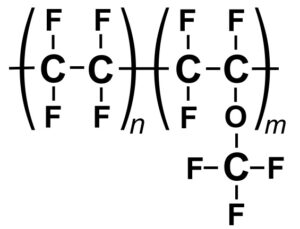

PVDF offers excellent resistance to most aggressive acids. It is known for its high purity and strength even at high temperatures (up to approx. 140 °C), which makes it ideal for applications where the highest demands are placed on chemical resistance, temperature and compressive strength. It is not suitable for alkaline media.

PP is a versatile material that is valued for its corrosion resistance and cost-effectiveness. It is suitable for a wide range of industrial applications. Polypropylene (PP) is lightweight yet robust, making it a cost-effective solution for many heat transfer applications.

PFA is known for its exceptional chemical resistance and high temperature tolerance. It is particularly suitable for extreme chemical environments. PFA also offers excellent abrasion resistance and is easy to clean, making it a preferred material for demanding applications in chemistry and research.

Stainless steel as a material refers to alloyed or unalloyed steel grades with a comparatively high chromium and low carbon content, which results in high temperature and corrosion resistance. Our stainless steel bath heat exchangers are primarily used in alkaline tanks and baths, e.g. in the alkaline degreasing of process parts in the electroplating industry.

| Material | Temperature range (°C) | Density (g/cm³) | Thermal conductivity (W/m-K) | Chemical resistance | Color |

|---|---|---|---|---|---|

| PE-RT | -30 to 80 | 0.94 | 0.40 | Acids, bases | yellow-white-opaque |

| PE-HD | -30 to 40 | 0.94 | 0.4 | Acids, bases | Black |

| PFA | -50 to 200 | 2.15 | 0.25 | Almost complete | transparent, slightly opaque |

| PP | 0 to 80 | 0.91 | 0.22 | Acids, bases | gray, black |

| PVDF | -20 to 130 | 1.78 | 0.18 | Highly concentrated acids, pure media | white-opaque |

| VA (Stainless steel) | -100 to 600 | 7.90 | 15.00 | Bases, light acids | Metallic silver |

Plastic heat exchangers offer numerous advantages that make them the ideal choice for a wide range of industrial applications:

By combining these advantages, CALORPLAST plastic heat exchangers offer an excellent solution for your heating technology needs – from energy efficiency and adaptability to long-term cost savings.

Case study no. 20: Sulphuric acid dilution Initial situation Large quantities of sulphuric acid…

Case study no. 15: Strip staining Initial situation Strip pickling is used for electroplating…

Case study no. 7: Stable ventilation in animal husbandry Initial situation Stables in animal…

Case study no. 19: Redox flow battery Initial situation When used as a redox…

Case study no. 8: Production of solar cells Initial situation One production step in…

Case study no. 5: Exhaust air purification in food processing Initial situation Modern waste management…

Case study no. 2: KVS laboratory building Initial situation Modern and regulation-compliant ventilation systems…

Case study no. 4: Stainless steel Immersion-Type heat exchanger for sealing baths Initial situation…

Case study no. 16: Plating om Plastics (PoP) Initial situation Although surface coatings in…

Case study no. 17: Phosphating Initial situation If base materials are to be phosphatized,…

Case study no. 1: Landfill leachate Initial situation The landfill water from the landfill…

Case study no. 10: KVS system in an electroplating shop Initial situation MAG values…

+49 (0)2151 - 8777-12

+49 (0)2151 - 8777-12