Biogas heat exchanger

The Calorplast biogas cooler is made entirely of corrosion-resistant polyethylene (PE), making it resistant to the aggressive substances in the biogas and…

Home | Gas-liquid Heat Exchanger

CALORPLAST gas-liquid heat exchangers

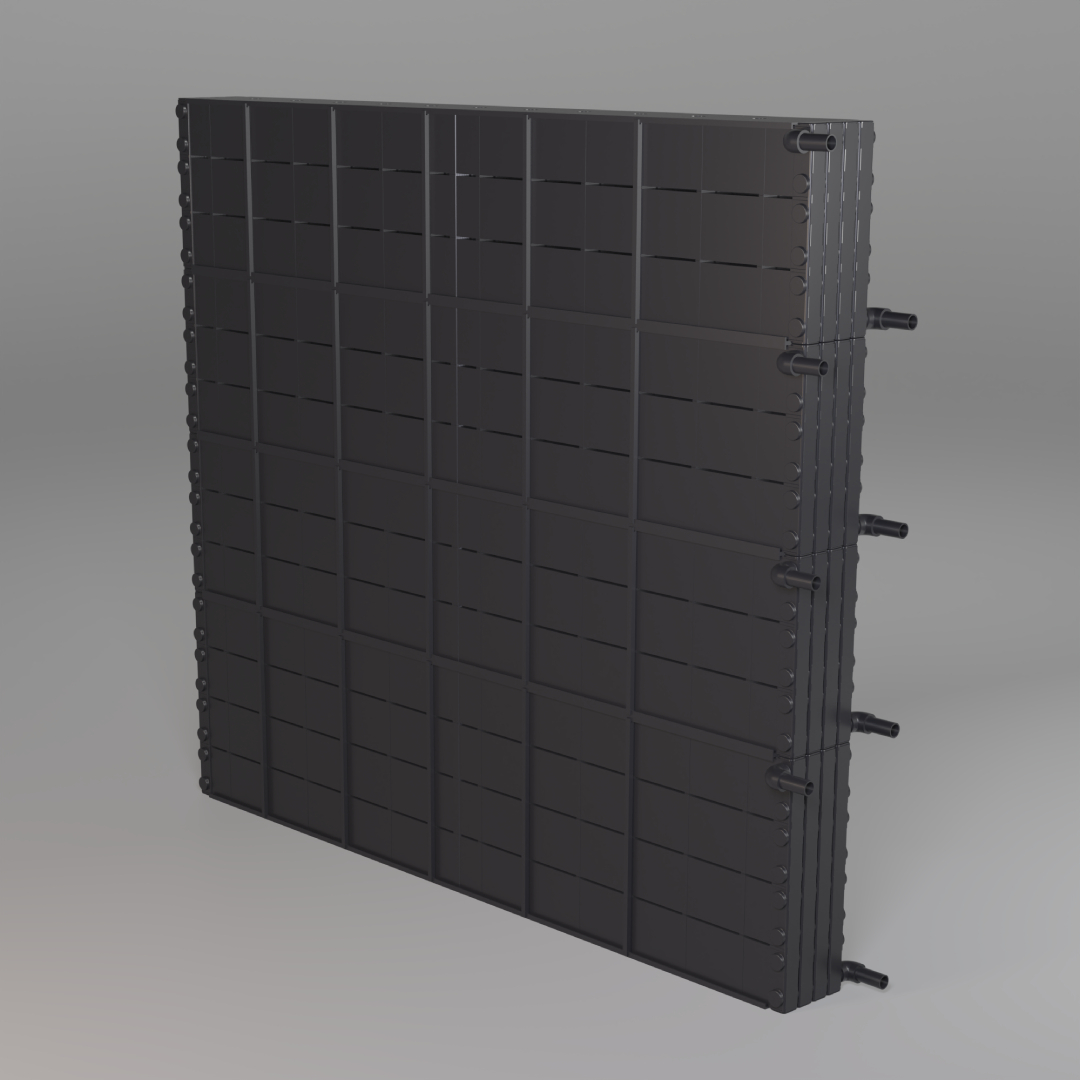

CALORPLAST gas-liquid heat exchangers have been the standard in the treatment of aggressive gas flows for over 40 years. Whether for cooling, heating or heat recovery: the unique, patented CALORPLAST technology, together with the design consisting entirely of corrosion-resistant engineering plastics, enables unrivalled efficiency, operational reliability and durability.

The modular design of the gas-liquid heat exchangers ensures seamless scalability of capacity and performance and can be flexibly adapted to a wide range of requirements. Gas volume flows from a few hundred to 80,000 m³/h can be realised.

This results in a wide range of applications:

– in heat recovery in combination with a closed circuit system (CCS) from aggressive or polluted exhaust air, e.g. in surface technology, chemicals, the electronics industry, laboratories in schools, universities, research facilities and similar institutions

– for cooling and heating aggressive process and exhaust gases, e.g. in drying technology, chemical metalworking, waste incineration, sewage sludge incineration, for cooling air flows with groundwater, seawater, etc., for cooling biofilters, in ventilation installations for clean room technology and in systems with high hygiene requirements.

– as a condenser for aggressive vapours in chemical and pharmaceutical industry and research, drying technology in circulation processes and for the recovery of highly volatile process media

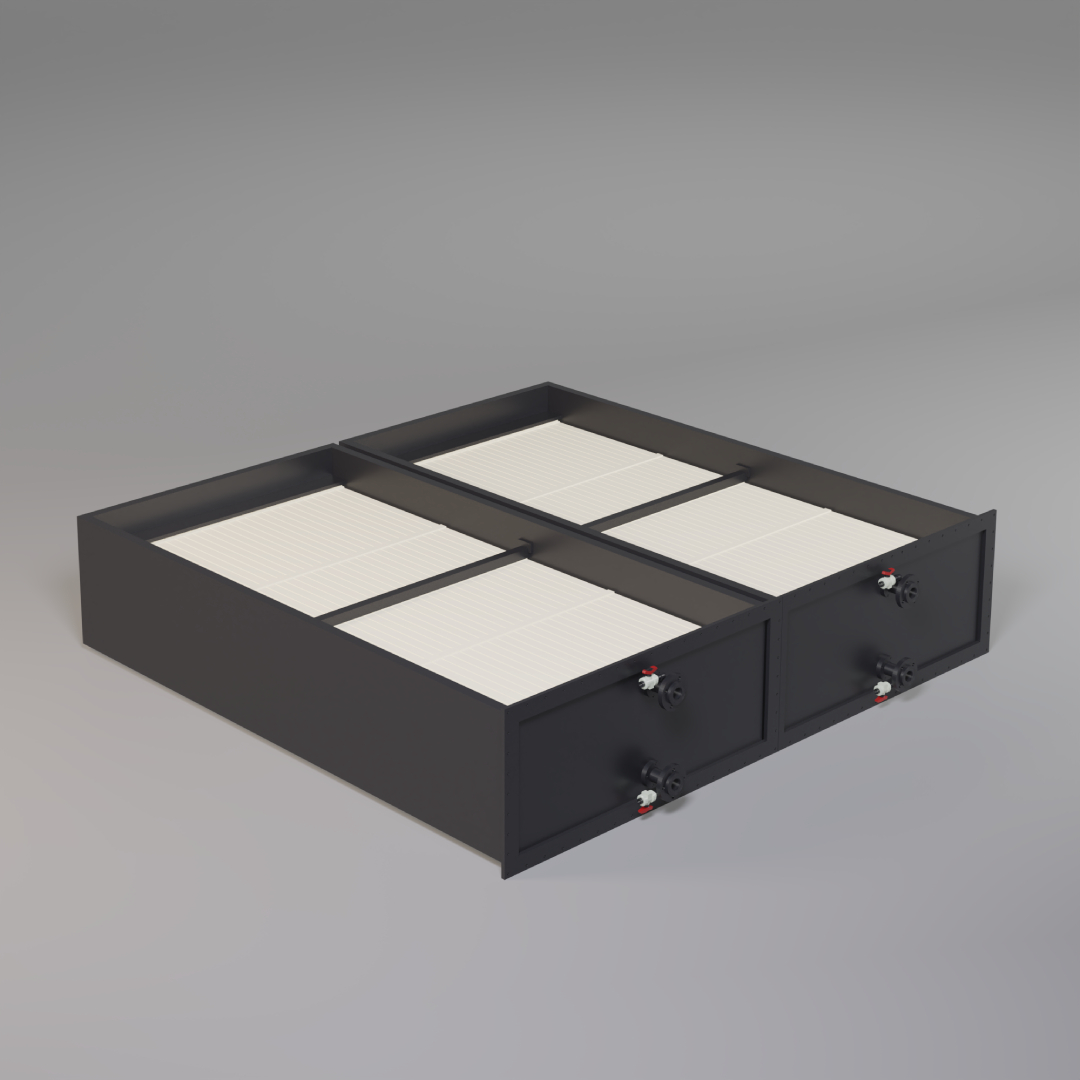

The gas-liquid heat exchanger consists of a modular base body, through which a heat transfer medium flows, and a housing made entirely of plastic. The housing is manufactured as a high-quality, ready-to-install duct section in PE or PPs (double-webbed plate or solid material) with flange connections and is designed for direct installation in the ventilation system. Decades of experience in the field of exhaust air and waste gas treatment, as well as heat recovery, enable us to advise you exactly according to your needs. With the help of computer-aided simulation, our engineers determine flow conditions, heat transfer and performance in such a way that the most cost-effective and efficient solution for all your requirements is achieved in every case.

Each gas-liquid heat exchanger can optionally be fitted with an additional droplet separator and condensate outlet. An optional plastic cleaning device is ideal wherever contaminated gases are to be expected. The open construction of the modular CALORPLAST design facilitates cleaning, e.g. with pressurised water.

This results in a fully operational device that can be installed immediately in exhaust air or process systems and used for many decades.

The air conditioning of aggressive and often heavily polluted air, as well as the use of groundwater as a cooling source, for example, does not allow the use of metal heat exchangers. Calorplast heat exchangers not only offer perfect hygiene and corrosion resistance thanks to their all-plastic construction, but can also be perfectly integrated into the barn structure thanks to their modular design.

The Calorplast biogas cooler is made entirely of corrosion-resistant polyethylene (PE), making it resistant to the aggressive substances in the biogas and…

In high-quality fattening and breeding farms, the climate in the barn is of crucial importance for animal welfare and product quality, not…

The use of techn. plastics not only prevents the occurrence of corrosion, but also allows use in a wide range of temperatures…

With the Evolution series of gas/water heat exchangers, CALORPLAST sets the standard for efficient heat recovery in aggressive and polluted exhaust air…

The unique, modular CALORPLAST technology also allows use in confined spaces or vertical gas flows. The gas-liquid heat exchanger is specially designed…

The gas-water heat exchanger consists of a modular base body, through which a heat transfer medium flows, and a housing made entirely…

+49 (0)2151 - 8777-12

+49 (0)2151 - 8777-12