- Sign up for our Newsletter!

- +49 (0)2151 - 8777-0

- info@calorplast.de

- Mon - Fri: 8:00 - 17:00

Efficient brick drying is a cornerstone of modern ceramic and construction material production. Especially in industrial settings, where energy consumption and process stability are crucial, innovative technologies like polymer-based heat exchangers are redefining standards. Whether in traditional or artificial drying of bricks, manufacturers are increasingly turning to corrosion-resistant and energy-efficient systems that ensure consistent drying performance while minimizing operating costs. At CALORPLAST, we support the brick and tile industry with customized solutions that not only enhance drying efficiency but also enable sustainable heat recovery from exhaust air, contributing directly to your energy and environmental targets.

Energy savings in brick drying at a glance

Key benefits briefly:

Efficient heat recovery makes brick drying more economical and future-ready.

Introduction: Energy requirements and challenges in brick drying

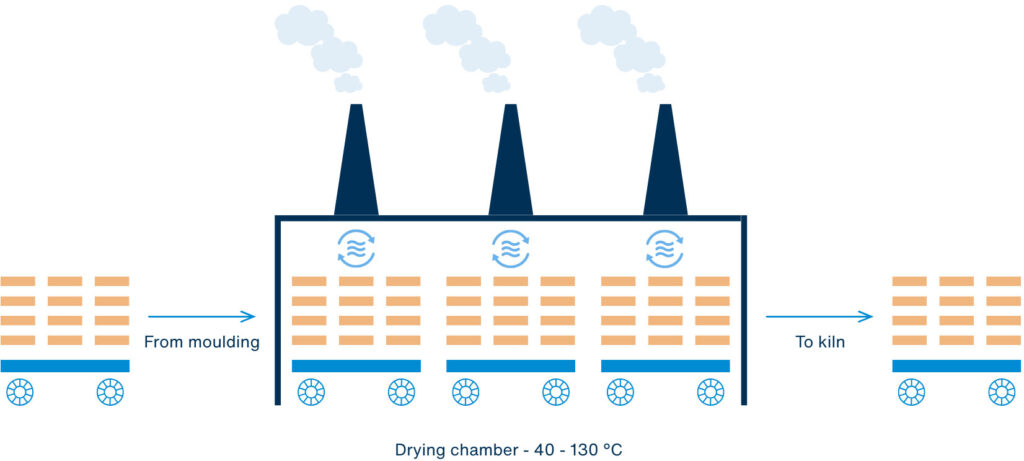

Brick drying is a critical stage in the production of ceramic and construction materials. Before firing, bricks must be carefully dried to prevent cracking and structural defects. This process typically requires large volumes of heated air, especially in tunnel and chamber kilns used for artificial brick drying. The exhaust air from these dryers represents the largest single energy consumer in the entire manufacturing process, often accounting for more than 50% of total thermal energy usage.

Given rising energy costs and increasing environmental regulations, the demand for energy-efficient solutions in brick drying has never been more urgent. Industrial operators are now seeking innovative ways to reduce energy consumption, recover waste heat, and optimize drying performance without compromising product quality. This is where advanced heat exchanger systems, designed specifically for high-moisture, corrosive environments, can make a decisive difference.

Challenges: Emissions, energy losses and regulatory requirements

In brick drying, industrial manufacturers face growing pressure from both regulatory authorities and operational demands. Modern brick drying processes require substantial amounts of thermal energy can also lead to the release of process-related emissions.

One of the key challenges is fluorine-containing exhaust air, which is commonly generated during the drying of clay-based materials. Fluorine compounds are highly reactive and can cause severe corrosion in metallic components, including conventional heat exchangers and ductwork. This results in higher maintenance costs, reduced equipment lifetime, and compromised process reliability.

At the same time, regulatory frameworks such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and assessments by the European Chemicals Agency (ECHA) are tightening permissible emission limits for industrial drying processes.

As a result, the continued use of non-resistant materials and outdated thermal systems is coming under increasing scrutiny—not only in terms of environmental impact, but also regarding workplace safety and legal compliance.

Key challenges at a glance:

Aggressive exhaust air

(e.g. fluorine, sulfur compounds) can severely damaga conventional drying and heat recovery systems

High energy losses

without heat recovery significantly increase operating costs

Growing regulatory pressure

from REACH and ECHA, including emission limits and material restrictions

Risk of future restrictions

on certain processes and materials if compliance thresholds are exceeded

Increasing demand

for durable, corrosion-resistant, and energy-efficient technologies

To remain competitive and compliant, manufacturers are re-evaluating their drying processes and investing in robust systems designed for harsh exhaust conditions – especially in energy-intensive artificial brick drying applications.

Technologies to increase efficiency in brick drying

Heat recovery with heat exchangers

In modern brick drying operations, heat recovery plays a decisive role in reducing energy consumption. Especially in energy-intensive artificial brick drying, where large volumes of high-temperature exhaust air are continuously discharged, a significant portion of thermal energy is lost unless it is recovered and reused.

High-efficiency heat exchangers are essential for capturing this unused waste heat. In aggressive exhaust air environments, however, conventional metal systems are highly susceptible to corrosion and fouling. This is where polymer-based heat exchangers offer clear advantages:

Corrosion resistance:

Ideal for exhaust air containing fluorine, sulfur, or other aggressive compounds

Long service life

Designed for 20+ years of operation in industrial drying environments

Low maintenance

Fouling-resistant surfaces help minimize cleaning effort and downtime

High thermal efficiency

Recovers a significant share of waste heat for preheating incoming air or process water

By integrating plastic heat exchangers into the drying line, manufacturers can achieve substantial energy savings, reduce CO₂ emissions, and improve overall process reliability.

Use of heat pumps in brick drying

Heat pumps are increasingly being adopted as an energy-efficient complement to conventional drying technologies. In artificial brick drying, they can be used to upgrade low-temperature waste heat to a usable level, making energy that would otherwise be lost available again for the drying process.

Key benefits include:

Reduced primary energy demand:

Waste heat is reused instead of being lost

Stable drying temperatures:

Consistent temperatures independent of outside air fluctuations

Synergistic operation

with heat exchangers and closed-loop systems

When integrated into a well-designed thermal concept, heat pumps can significantly reduce both operating costs and carbon footprint.

Concepts for reducing exhaust air losses

In many brick plants, a substantial amount of energy is still lost through uncontrolled or insufficiently optimized exhaust airflows. To address this, several technical approaches can be implemented to minimize unused heat losses and improve overall system efficiency:

Closed-loop air systems:

Reuse part of the warm exhaust air to reduce fresh air demand

Controlled exhaust air discharge:

Adjust volume flow based on real-time drying requierements

Integrated bypass systems:

Optimize airflow routing for varying load conditions

Condensation recovery:

Capture latent heat from water vapor in the exhaust

Combined with heat exchangers and heat pumps, these measures provide a holistic strategy for improving efficiency in brick drying operations while supporting compliance with increasingly strict energy and emission regulations.

Decarbonization of process heat: CO₂-free brick production as a goal

For industrial manufacturers, reducing CO₂ emissions is no merely a regulatory requirement, it has become a strategic priority. In brick drying, a major share of emissions originates from the generation of process heat. Particularly in artificial brick drying, fossil energy sources are still widely used to achieve the required drying temperatures, resulting in significant carbon output.

To move toward CO₂-free brick production, one of the most effective levers is the integration of heat recovery into the thermal process. By reclaiming energy from hot exhaust air streams, less primary energy is required for preheating and process heating, directly reducing CO₂ emissions.

Plastic heat exchangers play a key role in this transition. Their corrosion-resistant design enables reliable long-term operation even in aggressive, high-moisture exhaust environments where conventional metal systems often fail. This makes continuous and efficient heat recovery possible, even under demanding drying conditions.

Key contributions include:

Stable energy recovery

in corrosive exhaust air applications

Reduced demand for fossil-based process heat

through reuse of recovered thermal energy

Lower CO₂ emissions

without compromising drying performance or product quality

By implementing polymer-based heat recovery solutions, manufacturers not only improve the energy efficiency of their drying processes but also take a decisive step toward climate-neutral brick production.