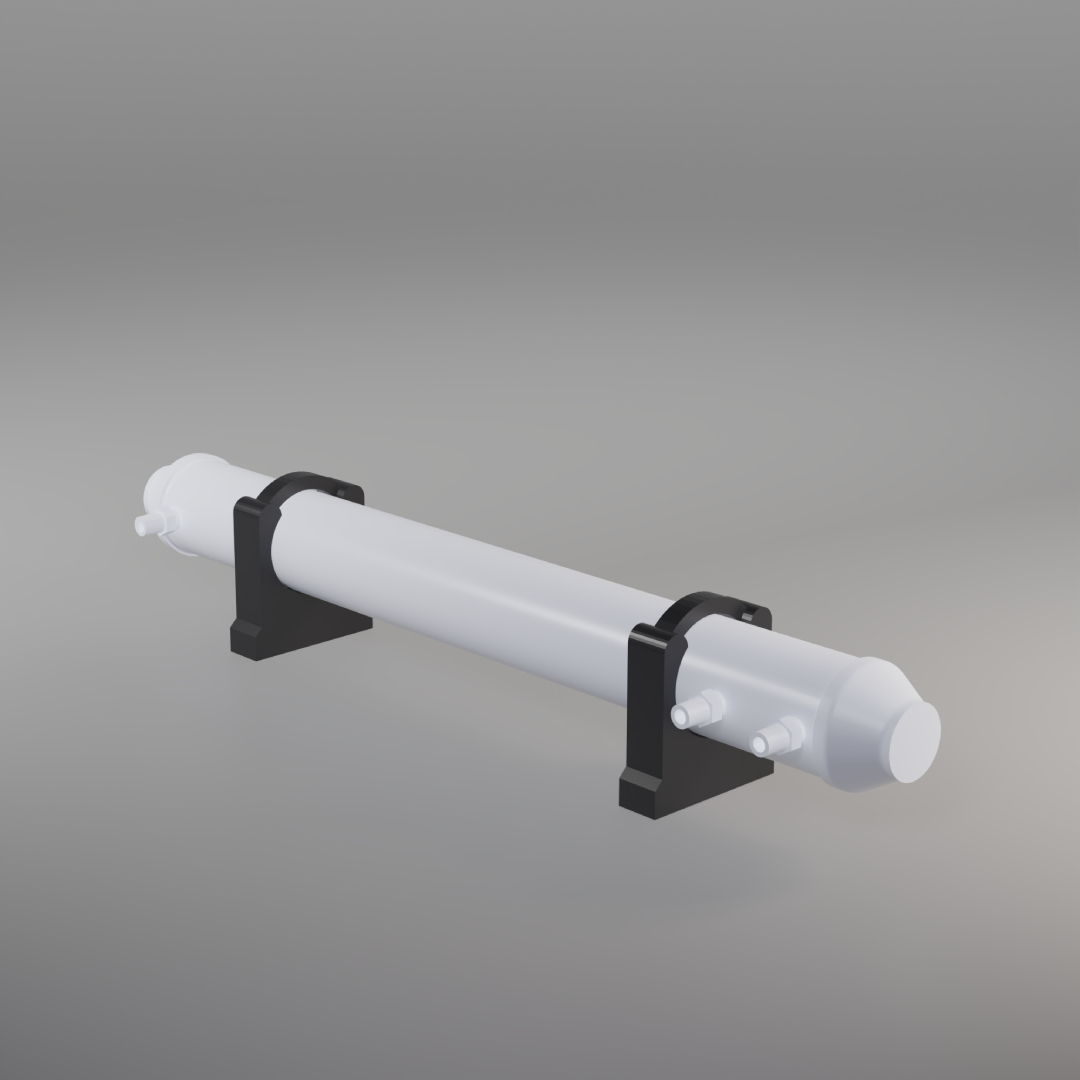

Tube bundle heat exchanger – flue gas treatment version

In the thermal treatment of waste, flue gas treatment is associated with special technical requirements. This poses a number of challenges, especially…

Home | Shell and Tube Heat Exchanger

CALORPLAST shell and tube heat exchangers

CALORPLAST shell and tube heat exchangers are external heat exchangers in a classic design that can be used to efficiently heat, cool and condense pure and ultra-pure media.

The complete design made of corrosion-resistant engineering plastics and the use of thin-walled tube bundles result in a compact design with a high heat transfer capacity.

This makes CALORPLAST shell and tube heat exchangers perfect for all applications where high demands are placed on purity and chemical resistance, e.g. in surface technology, the chemical industry and research, as well as semiconductor technology and seawater aquariums.

Each tube bundle heat exchanger consists of a tube bundle made of thin-walled plastic tubes, casing tube and tube sheet plates, which can either be welded or screwed together. Material combinations of different plastics are also possible. Installation at the customer’s premises can be carried out both horizontally and vertically.

Thanks to the use of corrosion-resistant plastics, cleaning can be carried out easily using chemical processes, resulting in low operating and maintenance costs.

The design is carried out according to customer requirements and is accompanied by a computer-aided simulation. The technical parameters of the tube bundle heat exchanger are determined according to optimised criteria and the most efficient and cost-effective solution is found.

In the thermal treatment of waste, flue gas treatment is associated with special technical requirements. This poses a number of challenges, especially…

Decades of experience in the engineering and production of plastic heat exchangers make CALORPLAST experts in even the most challenging projects. Our…

The scaling of the pipe bundle parameters allows adaptation to the customer’s requirements. This means that even larger flow rates and outputs…

CALORPLAST shell and tube heat exchangers have been valued for decades in areas with high demands on cleanliness and chemical resistance. The…

+49 (0)2151 - 8777-12

+49 (0)2151 - 8777-12