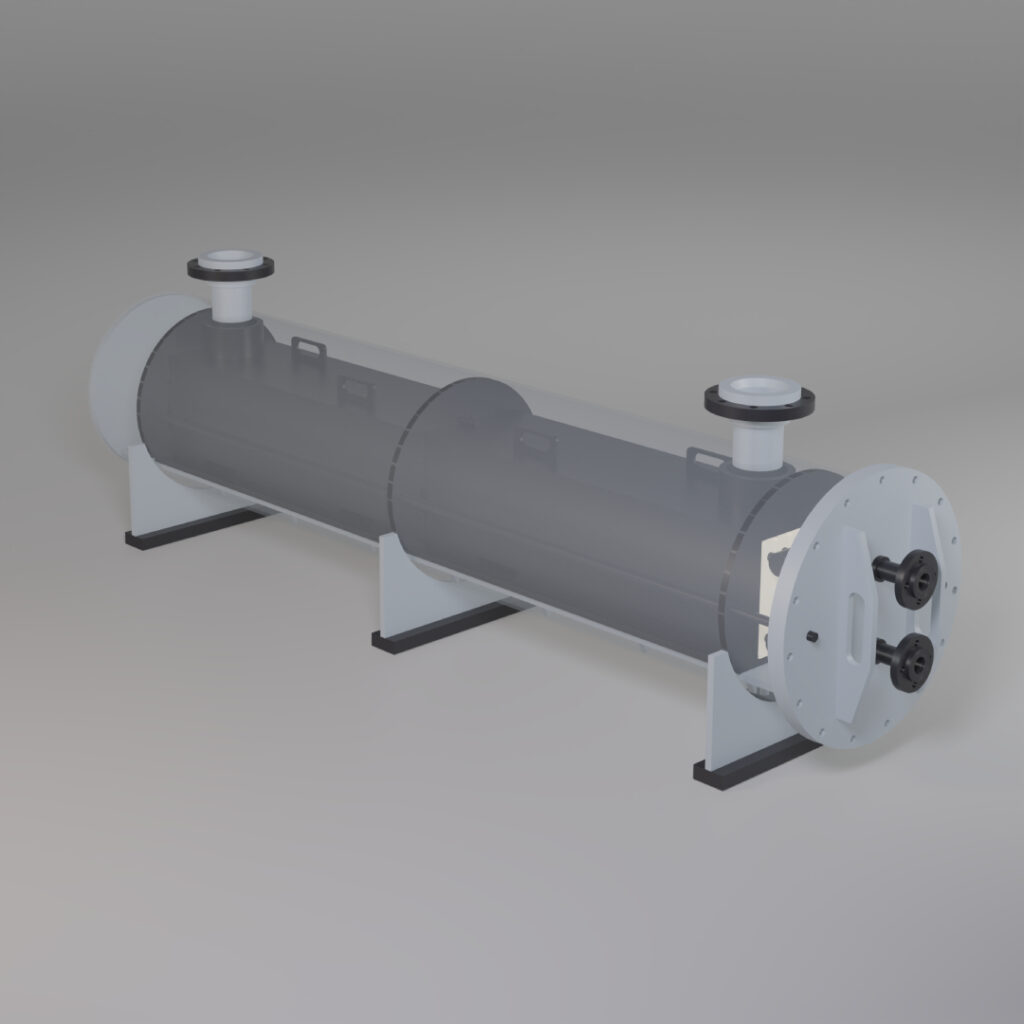

In the thermal treatment of waste, flue gas treatment is associated with special technical requirements. This poses a number of challenges, especially if the waste heat it contains is to be utilized. In addition to SO2, SO3 and NOx, traces of hydrofluoric acid (HF) or hydrochloric acid (HCl) can also occur in the flue gas, making the use of conventional metal heat exchangers impossible. CALORPLAST heat exchangers are made entirely of plastic and are therefore completely corrosion-resistant. CALORPLAST heat exchangers are used in waste heat recovery from waste or sewage sludge incineration wherever the flue gas has already been cooled in previous stages.

- Sign up for our Newsletter!

- +49 (0)2151 - 8777-0

- info@calorplast.de

- Mon - Fri: 8:00 - 17:00