Immersion-Type heat exchanger

CALORPLAST plastic Immersion-Type heat exchangers have been setting standards in the heating or cooling of highly concentrated, inorganic acids, high-purity media or…

Home | Immersion-Type Heat Exchanger

CALORPLAST plastic Immersion-Type heat exchangers

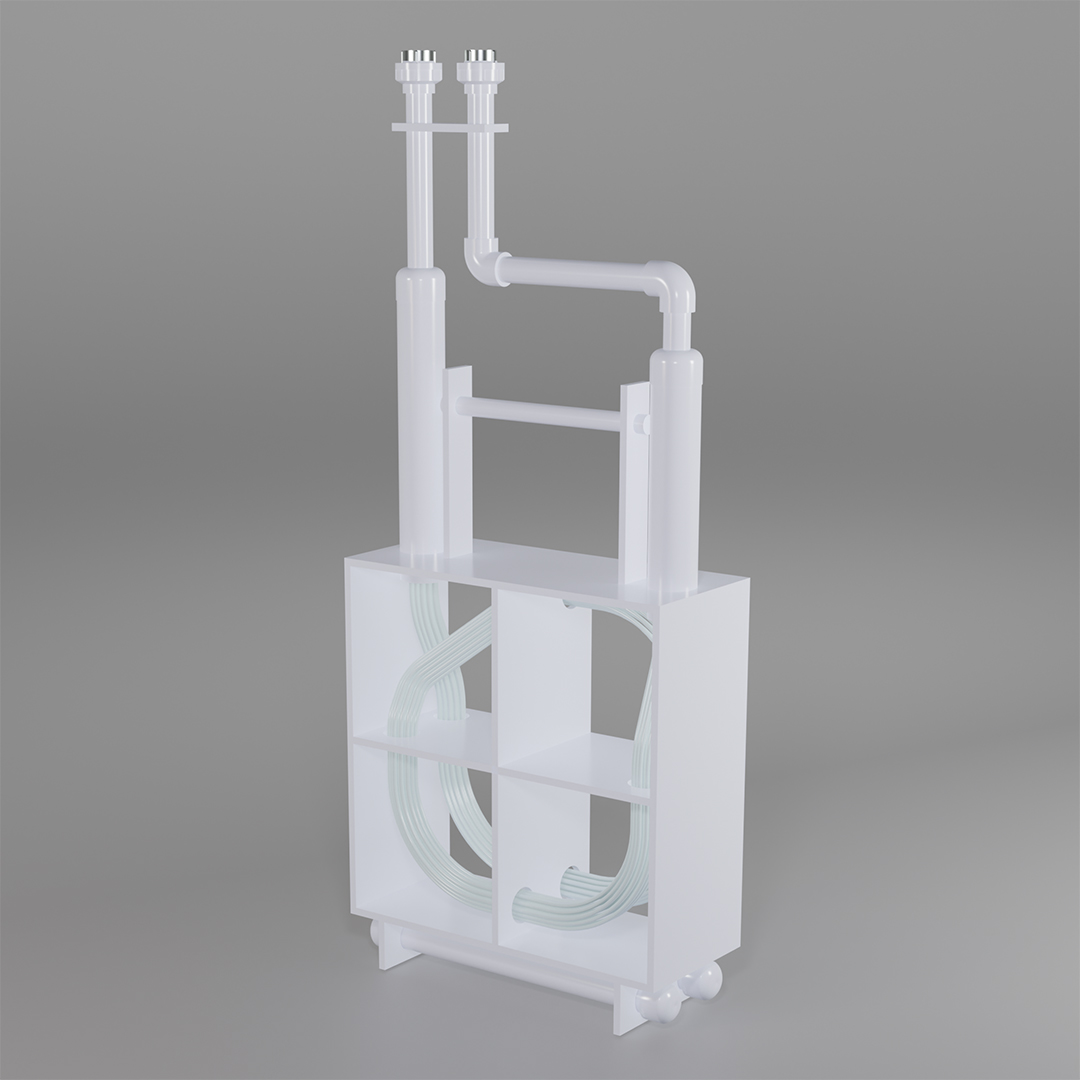

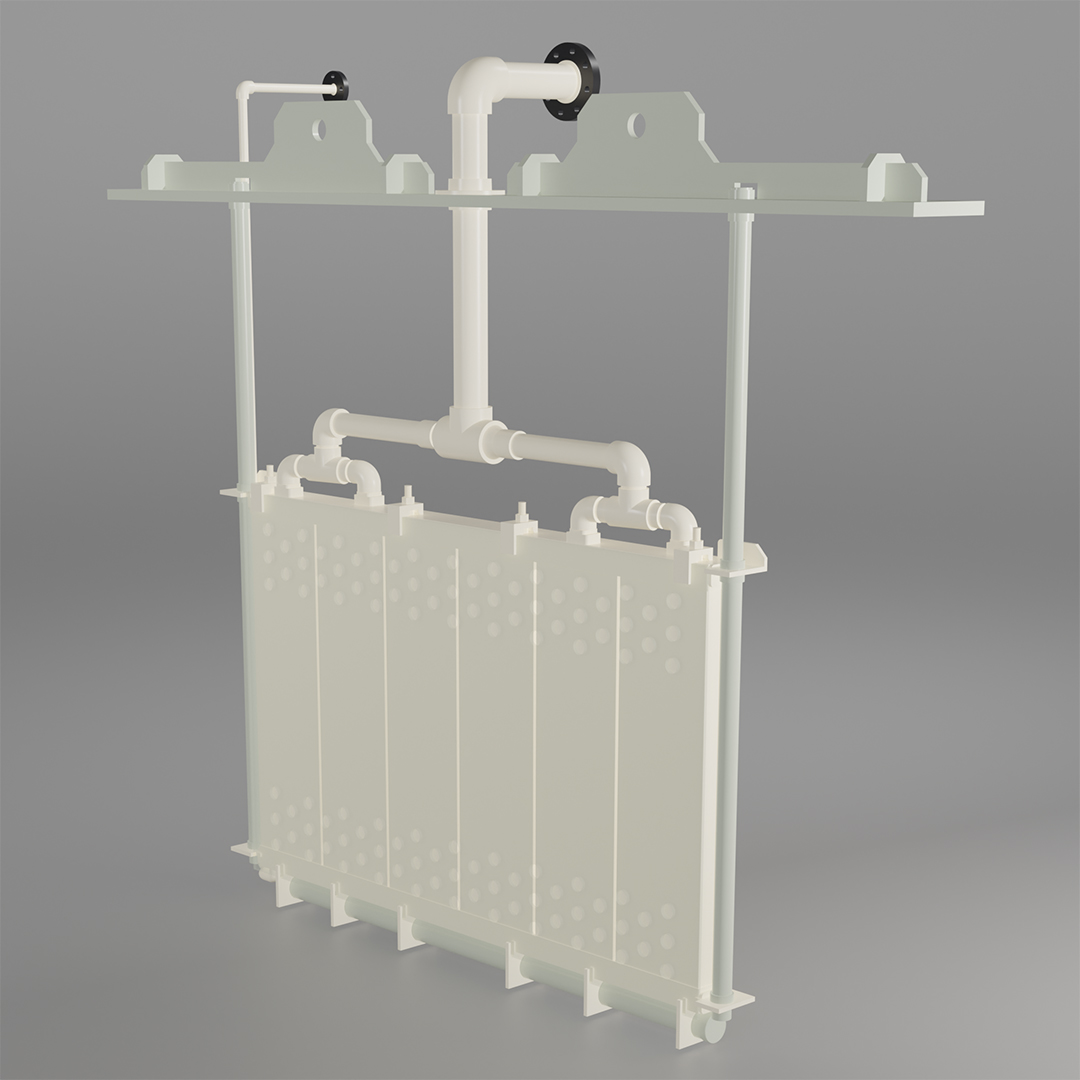

CALORPLAST plastic Immersion-Type heat exchangers have been setting standards in the heating or cooling of highly concentrated, inorganic acids, high-purity media or aggressive and encrusting liquids for over 40 years. The combination of the unique CALORPLAST module technology with corrosion-resistant engineering plastics results in a compact design with high heat transfer performance.

This makes CALORPLAST Immersion-Type heat exchangers reliable companions in all industries where the highest demands are placed on performance and economy. CALORPLAST has been trusted for decades in surface technology, the chemical industry, cooling battery acid and electrolytes, seawater applications and many other sectors.

Each Immersion-Type heat exchanger is adapted to the process requirements in a computer-aided simulation and manufactured according to customer specifications. The basic structure consists of many thin-walled tubes, which are joined together to form a module using a patented manufacturing process. These modules can then be welded together, piped and the heating or cooling flows can be switched internally to achieve the highest surface density with the lowest pressure losses. As a result, the transferable output often exceeds comparable metal Immersion-Type heat exchangers in conventional tube or plate design with comparable installation space. The open design of the tube packs not only increases the efficiency of the heat transfer and promotes the circulation of the bath media. It also makes cleaning and maintenance easier, as even simple mechanical damage can be repaired on site.

CALORPLAST Immersion-Type heat exchangers do not consist of metallic base bodies that are subsequently coated, but are made entirely of plastic. This means that there is no risk of creeping corrosion in the event of mechanical damage. The relatively low weight also makes installation and removal easier. The plastic Immersion-Type heat exchangers can therefore also be cleaned and maintained regularly with pressurised water, steam or chemical processes, which guarantees a long service life.

CALORPLAST plastic Immersion-Type heat exchangers have been setting standards in the heating or cooling of highly concentrated, inorganic acids, high-purity media or…

Process media that are stored in external storage tanks can be conditioned, heated or cooled with CALORPLAST bath heat exchangers in a…

The high level of adaptability also extends to the smallest sizes: even in the smallest electroplating and chemical tanks – such as…

PFA (perfluoroalkoxy) is often used as a heat exchanger material where the highest standards of chemical resistance are required. CALORPLAST uses this…

Where high temperatures meet high outputs, steam is a crucial heating medium. With the CALORPLAST concept, steam-operated, corrosion-resistant heat exchangers with the…

Thanks to their modular design, Calorplast bath heat exchangers can be scaled almost indefinitely and meet the highest requirements for heating or…

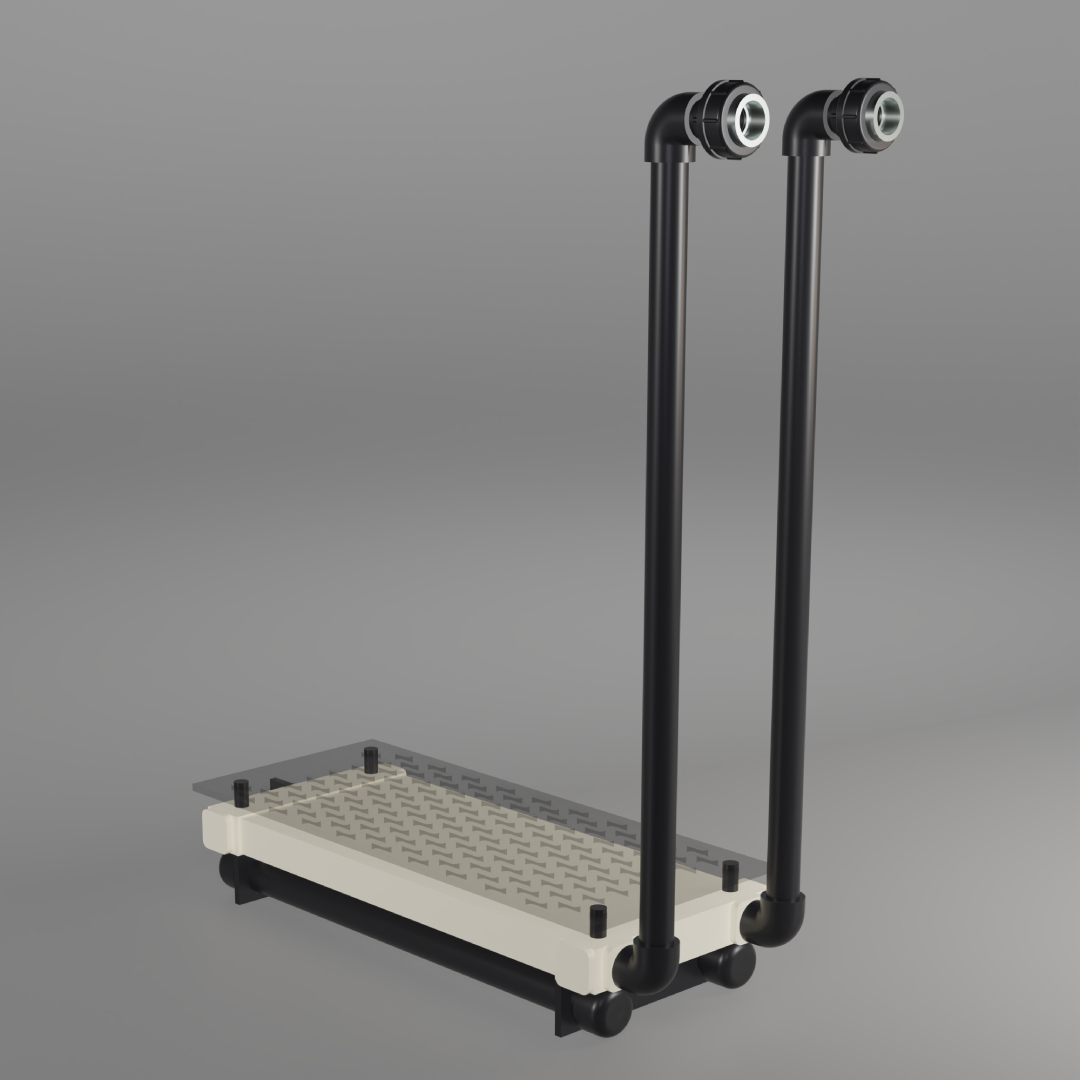

The unique, modular CALORPLAST concept also proves its worth when used with low strip plating tanks or when placed on the tank…

Stainless steel bath heat exchangers are used wherever high temperatures meet alkaline process media. In contrast to conventional Immersion-Type heat exchangers with…

+49 (0)2151 - 8777-12

+49 (0)2151 - 8777-12